- Function

- Application

- Compatibility

- Temperature and pH Considerations

- Durability

- Concentration and Dosage

Polymeric Anti-Tinting Agents

These agents form a polymeric film or coating on the fabric surface, creating a barrier against dye migration.

Surfactant-Based Anti-Tinting Agents

Surfactants can be used to control the migration of dyes by altering the wetting and swelling properties of the fibers.

Biodegradability

The environmental impact of anti-tinting agents is an important consideration. There is a growing interest in developing environmentally friendly formulations.

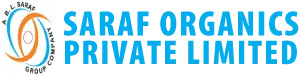

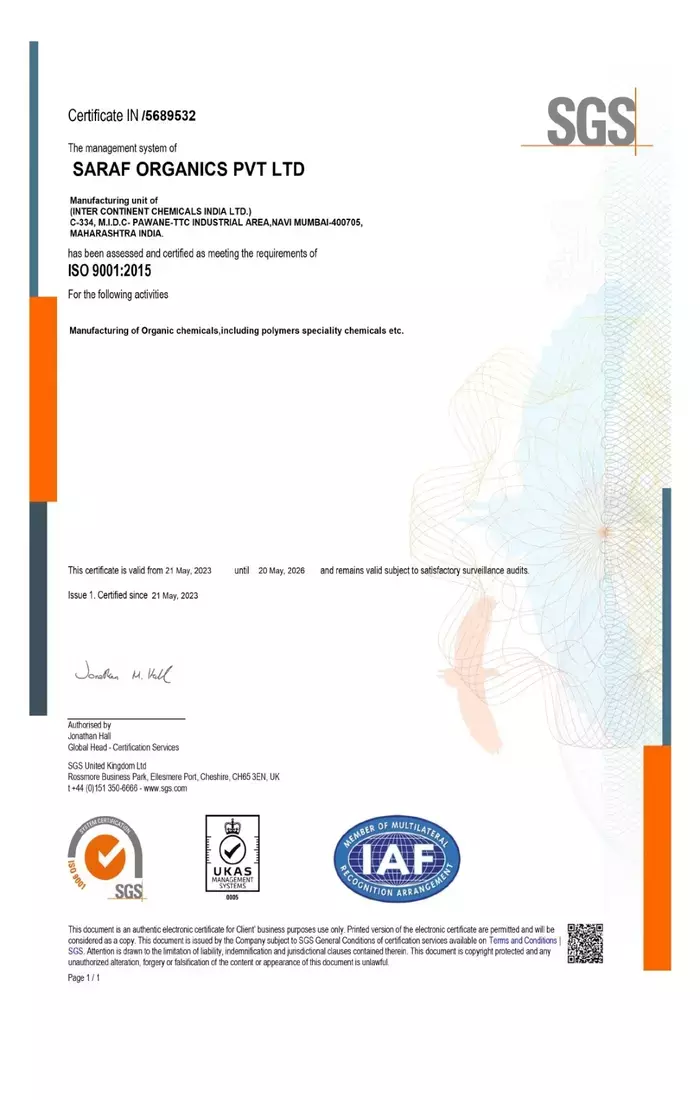

Regulatory Compliance

Manufacturers must adhere to regulatory standards and guidelines for textile chemicals.

Padding

Anti-tinting agents are often applied through padding methods, where the fabric is immersed in a solution containing the anti-tinting agent.

Exhaust Application

In exhaust application, the anti-tinting agent is applied to the fabric during the dyeing or finishing process.